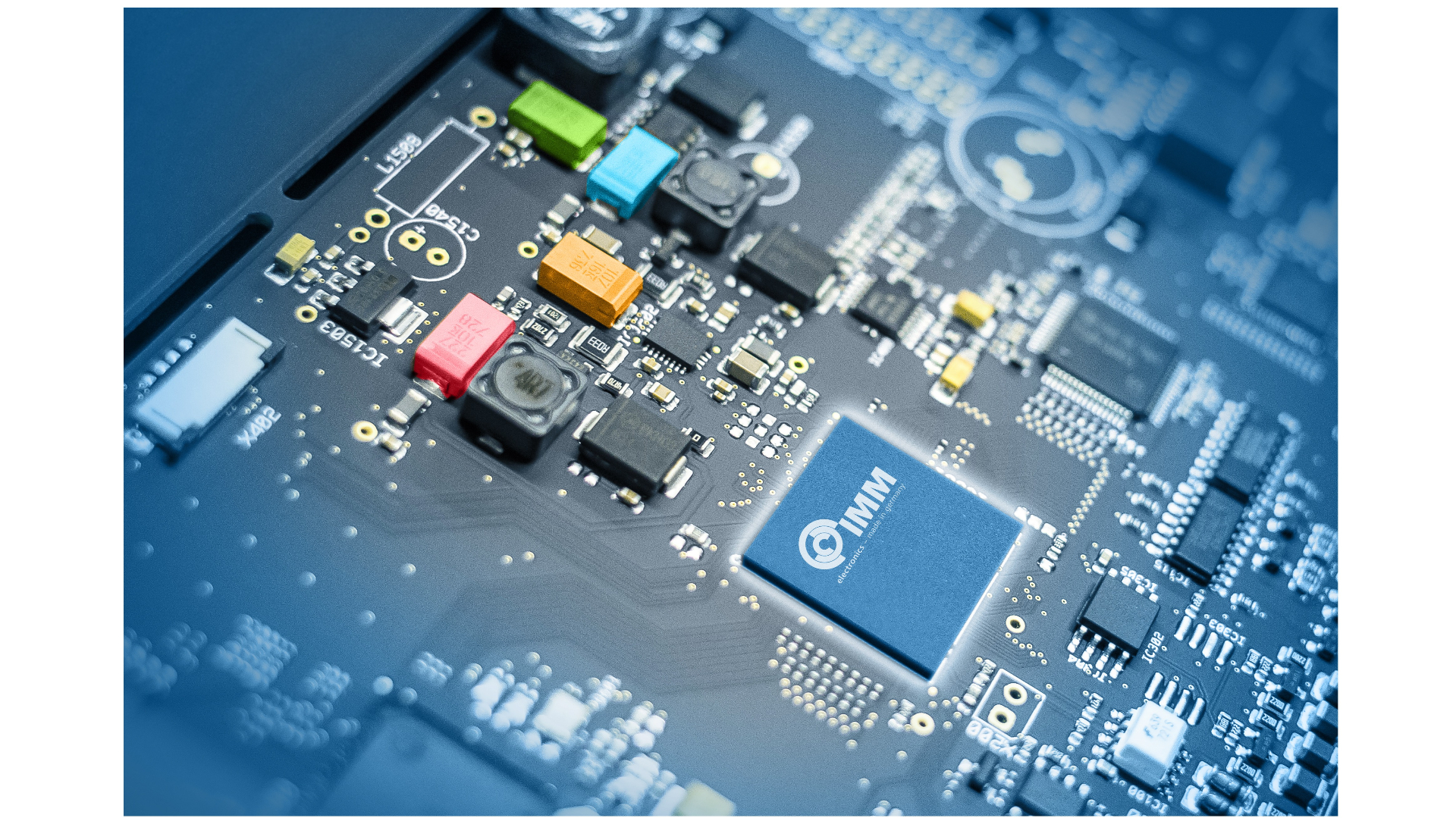

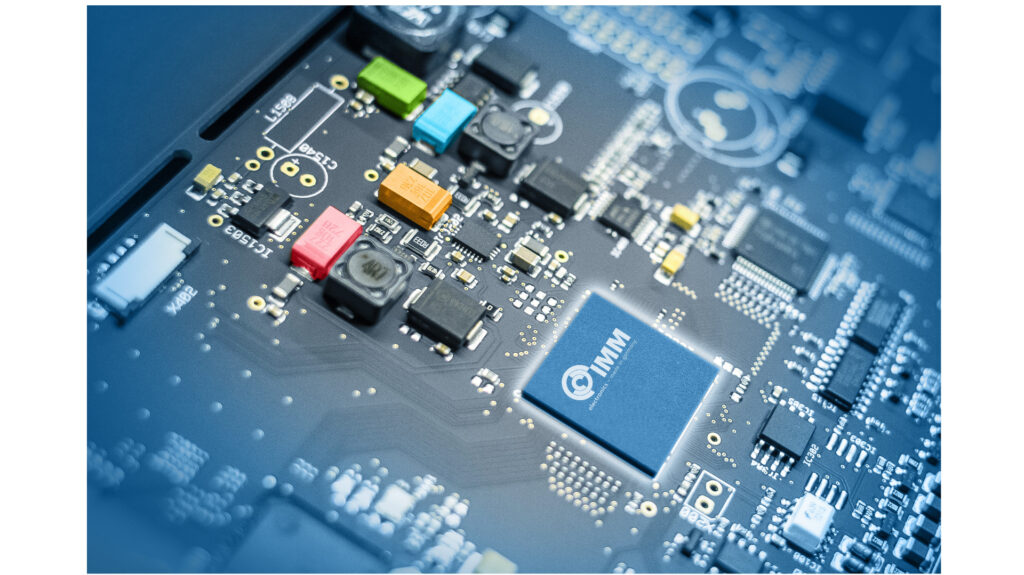

We are continuously developing our production. With two new systems, we are taking proven services such as component encapsulation and circuit board cleaning to a new technical level.

Encapsulation restructured with a 2-component dispensing system

The precise encapsulation of components has long been part of our service portfolio. An automated 2-component dispensing system is now in use. It ensures even greater process reliability, bubble-free processing, and consistent quality. Mixing ratios, feed speed, and dispensed quantity can be precisely controlled. This not only improves precision but also the cost-effectiveness of series production.

PCB cleaning now in-house

Cleaning components and misprints is also nothing new to us. What’s new is that this process is now handled in-house. With the SYSTRONIC CL902, we clean components directly on-site – quickly, reliably, and residue-free. The automatic multi-phase process (cleaning, rinsing, and drying) reduces throughput times, increases flexibility, and eases the burden on logistics. The close integration with production brings additional benefits for quality and planning.

These two investments demonstrate how we are systematically modernizing existing processes. They are integrated with the latest technology standards and are process-oriented, always with the goal of offering our customers maximum reliability and efficiency.