For a long time, grey, rectangular enclosures dominated industry, mechanical engineering and infrastructure. This design is still in demand because it is robust, space-saving and versatile. At the same time, requirements have changed: design, feel and usability now play a central role wherever electronics are visible and used regularly.

‘Today, an enclosure is much more than just a protective shell,’ says Mathias Bünte from BOPLA. ‘It becomes a visible part of the product and a carrier of brand and product values. Especially with complex technology, the external appearance is becoming increasingly important.’

From protective enclosure to user interface

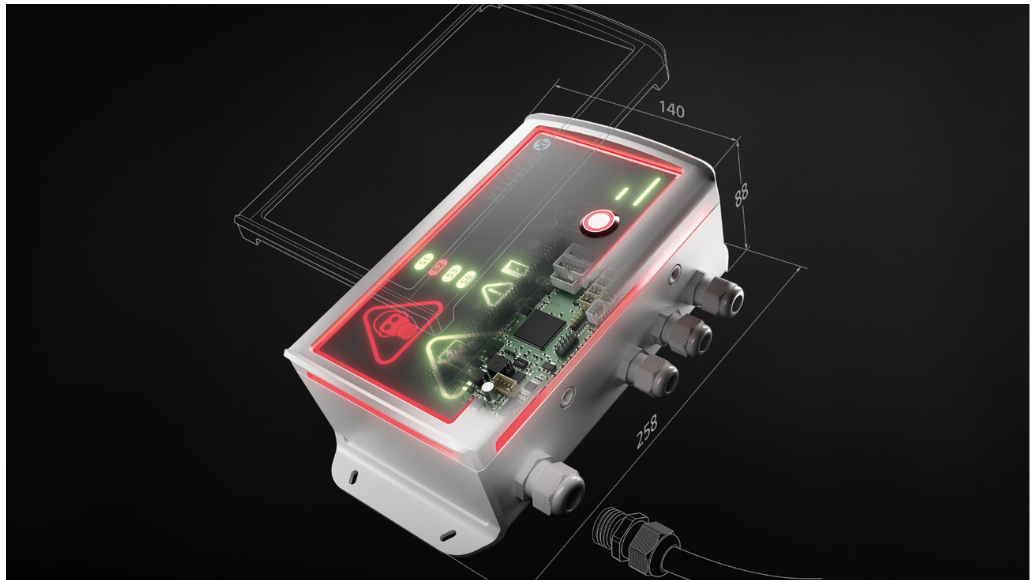

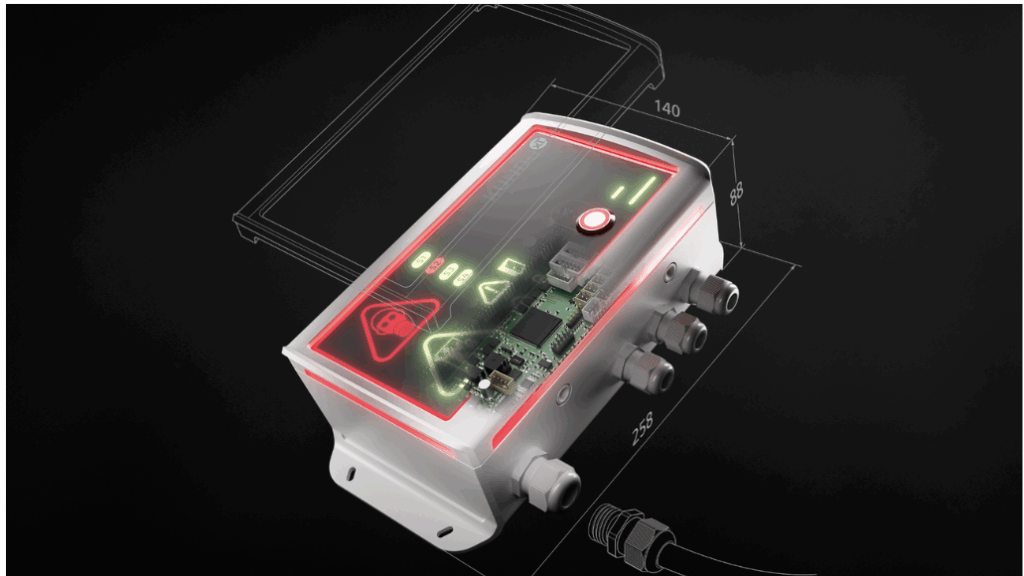

This development is driven by modern operating concepts from consumer electronics. Enclosures are increasingly functioning as three-dimensional user interfaces. In addition to buttons, switches and indicator lights, digital components such as touch displays, sensors, light elements and antennas are being integrated.

BOPLA develops enclosures that meet these requirements while also incorporating the brand’s colour and design language. This allows industrial devices, such as controls in agricultural or construction machinery, to be integrated into a holistic brand experience.

Material and manufacturing diversity

This diversity is based on a broad spectrum of manufacturing and processing technologies. In addition to plastic injection moulding, aluminium profile, aluminium die-casting and stamping-bending technology, BOPLA also relies on additive processes such as 3D printing.

Customised solutions are also possible for surfaces and colours. The high level of vertical integration enables machining, coating, painting, printing and system integration from a single source.

‘We can produce both large series and small, exclusive quantities,’ says Bünte. ‘From housing machining to the integration of electronic components, we create solutions that are precisely tailored to our customers’ requirements.’